Sew-along with us!

Perhaps you'd like some company while you sew? We've sewn up each of our patterns and photographed each step along the way. Find the pattern you're after in the filter drop down below left.

Sew-Alongs

Sombrio Polo Sew-Along: Day 1 - Brief History of the Polo Shirt & what you need to make your own!

Have you ever wondered about the history behind the classic polo shirt? The polo shirt, also known as a tennis shirt or golf shirt, has a rich history that dates back to the early 20th century.

Origins in India

The polo shirt goes back to the sport of polo, which originated in India in the 19th century. British soldiers in India, during the colonial period, were introduced to the game of polo by the locals. The soldiers adopted the sport and its attire, including the comfortable and breathable polo shirt and brought the polo shirt back home.

Rise to Popularity

As the sport of polo gained popularity in England and other parts of the world, so did the polo shirt. Famous French tennis player René Lacoste popularized the polo shirt in the 1920s. Lacoste, known for his style and innovative approach to sportswear, created a short-sleeved, piqué cotton shirt with a buttoned placket and a soft collar. This design was a departure from the traditional long-sleeved, button-up shirts worn by tennis players at the time.

Since then, the polo shirt has become a versatile and essential piece of clothing for men and women outside of the sporting world. Its timeless design, comfortable fit, and sporty aesthetic make it a go-to option for casual and semi-formal occasions. Whether you're hitting the golf course, heading to a casual Friday at the office, or simply running errands on the weekend, the polo shirt is a classic choice that never goes out of style.

What you need to make your own Polo Shirt

The characteristics of a Polo shirt come down to just a few things. Fit, a short front placket, collar, and specific fabrics. We've got the fit and constructions details for you with the Sombrio pattern, but here is some information on the other items you'll need!

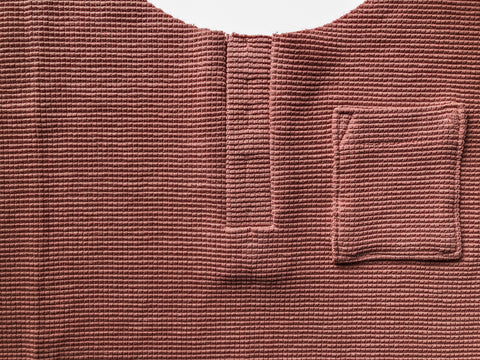

Cotton Pique

Pique is a style of weaving fabric with a subtle texture. The construction of the weave can resemble different patterns, such as waffle, honeycomb, birds-eye, and bullseye. The texture and pattern can best be seen up close.

Sombrio Polo Sew-Along: Day 2 - Front Placket & Back Yoke

Sombrio Polo Sew Along: Day 3 - Sew Shoulders, Assemble & Attach Collar

Fold the placket pieces towards center front. Push the bottom edges of the placket to the wrong side of the front through the opening. Position the placket pieces so that the left front placket is overlapping the right front placket.

At the bottom of the placket, use a straight stitch to stitch either a small rectangle or square and decorative “X” through all layers.

Sombrio Polo Sew Along: Day 4 - Sleeves + Hem

Timberland Henley Sew-Along - Day 1: Gathering Materials

The Timberland Henley, the newest member of our Parkland Collection and women's version of the Strathcona Henley, is a casual everyday wear garment to add to your wardrobe. This pattern comes in two variations, has a scoop neckline, and a curved hem that is lower in the back. You can choose between long or short sleeves, chest pockets, or add a Henley placket to the front neckline. In our sew-along, we will go over detailed instructions on how to assemble a Henley placket in two ways.

To begin, pick which variation you would like to make. Then, pick your size.

Please refer to your instruction booklet on how to take your measurements and determine which size works best for you. You can also refer to our Woodley Tee Sew-along where we go into similar detail on which measurements to account for, and which ones you can adjust on the pattern.

If you need to lengthen or shorten the pattern, it is very important to use our lengthen/shorten lines provided on the front and back pattern pieces. Due to the curvature of the hemline, it is best to make adjustments at the lengthen/shorten lines to keep the correct shape of the hem.

Fabric

When choosing fabric for your Timberland Henley, we highly suggest picking out a cozy light to medium-weight knit fabric that will soften over time. A medium-weight knit will be easier to sew with, especially if you are planning to make the Henley placket detail. A lightweight knit fabric may be a little trickier to sew with but could make for a perfect summer lounge tee. If you are not sure what type of fabric to look for, think of your favorite t-shirt that you already own and check the fabric weight and content.

When designing the Timberland Henley, we had a vision of a traditional Henley shirt made in waffle knit fabric that could be a great stand-alone or layering piece. Waffle knit fabrics tend to be more available in cooler weather seasons. For our photo sample, we used a waffle knit from Blackbird Fabrics that unfortunately sold out quickly. We hope they bring it back for next fall/winter ;)

Here are some recommendations for online stores that are currently carrying waffle knit fabrics:

Organic cotton waffle knit from I See Fabric

Cotton/spandex waffle knit from Style Maker Fabrics

Here are some non-waffle knit fabrics that are also great for creating the Timberland T-shirt variation:

Hemp/organic cotton jersey knit from Blackbird Fabrics

Mid-weight cotton jersey from Style Maker Fabrics

Some fun bold stripe cotton interlock fabric from Blackbird Fabrics

Optional: Use a matching or contrast ribbing for the neckband of your Timberland Henley or t-shirt. Check your favorite fabric store for their rotating stock on ribbing fabrics. Pictured here is ribbing from Blackbird Fabrics

The only hardware needed for the Timberland Henley is snaps or buttons for the placket variation. You can choose to use sew-on snaps, set-in snaps, or buttons.

Getting Started:

Before our next installment of the Timberland Henley Sew-along refer to our previous tutorials and posts about helpful tips to set up your sewing machine, get your sewing space ready, and how to cut out your pattern pieces from knit fabric:

Check out these tools and accessories from our Haberdashery that could help create your Timberland Henley:

Timberland Henley Sew-Along - Day 2: Placket #1

Timberland Henley Sew-Along - Day 3: Pocket and Placket #2

Timberland Henley Sew-Along - Day 4: Neckband, Sleeves, Hem

Bamberton Shorts Sew-Along: Day 1 - Gathering Materials and Choosing a Size

- Ribbed Knit Material (if you've chosen to sew a knit waistband): Look for 1X1 ribbing that is quite thin. Anything thicker than t-shirt weight will result in a waistband that is too bulky. If you're choosing a knit waistband for comfort, I'd recommend finding something made from bamboo or a bamboo/cotton blend...so soft!

- Pocket Lining Material: This can simply be your main/self fabric or you can have fun by adding a secret print (quilting cotton or other thin material) or something suited to your intended purpose for the shorts. For example, if you're sewing quick-dry activewear or swimwear you could look for a mesh material that keeps your shorts light and quick-drying.

- Elastic: The pattern calls for 3/4" elastic which is narrower than the finished waistband. The elastic fits within the drawstring channel so the area above and below the elastic is left unstructured for a very casual looking effect and a comfortable unconstrained feeling when worn. If you prefer a more structured waistband you can choose elastic up to 1 1/2" thick to fill the entire waistband and provide more firm support around the waist. Simply widen the drawstring channel topstitching to match the width of the elastic you chose. Look for braided elastic and, if you are sewing the shorts as swimwear, look for chlorine resistant elastic specifically. If you have a woven elastic in your stash this could work too as long as it isn't especially thick and rigid. The main aim is comfort here!

- Interfacing: Any light to medium weight woven interfacing will work! It is used to add structure to the drawstring buttonholes and some of the other small design details.

- Drawstring Cord: The cord you choose can really alter the look of the finished shorts. If you're after something beachy and summery, choose a double woven 5mm cotton cord and simply knot the fraying ends. If you'd like to create activewear, search for something flat like a shoe lace (in a pinch, if you want to shop local and can't find the cord you are after, simply repurpose two shoelaces by sewing them together to create your cord. The seam where they join will be hidden in your drawstring casing).

- Thread: Remember to select thread colors to suit each of your contrast details unless you want visible topstitching!

- 2 Buttons (for the patch pocket variation): Any flat style of button measuring 5/8" will work here. Avoid anything with a shank and much depth as these buttons will be sat on!

- Aglets (optional): If you are knotting your drawstring ends you will not need aglets. Likewise, if you are using shoelaces, your aglets will already be installed. There are many styles of aglets or drawstring end caps. You could even add beads to the end of your drawstrings to contribute to the overall style of the shorts!

Bamberton Shorts Sew-Along: Day 2 - Back Welt Pockets

Bamberton Shorts Sew-Along: Day 3- Back Patch Pockets

Today we are sewing the back patch pockets for Variation 1 and 3 of the Bamberton shorts. Before we begin, make sure that two of your four back pocket flaps are interfaced.

Assemble the flaps by placing one interfaced and one non-interfaced flap with right sides together. Repeat for the second flap. Sew around the sides and bottom edge using a 5/8" seam allowance. Reduce bulk if needed by grading one seam allowance shorter than the other and by clipping the corners.

Flip the pocket flaps right side out and press crisply. Finish them off by topstitching and/or edgestitching. Depending on the look you are after for your shorts you might like to complete your shorts with minimalist edgestitching 1/8" from the pocket flap edge (and then repeat this style of stitching whereever topstitching or edgestitching is called for. This is a great look for color blocked shorts and swim shorts in particular.

To create a more rugged look, add a second row of stitching 1/4" inwards. This is called topstitching. It is a great choice aesthetically for hiking shorts and any shorts sewn with a more rigid and sturdy fabric.

Complete the flaps by creating a vertical buttohole to suit the size of your chosen button.

Let's move on to the patch pockets themselves. Above you can see we've finished the raw edges of the pocket. This is optional and is a nice way to prevent wear on the pockets if they will be used often as the constant in an out of a phone or wallet can fray unfinished edges.

Turn under the pocket hem along the first notch. Turn under again at the second notch to create a wide hem. Press.

Stitch across the pocket opening hem to secure it. Our instructions suggest stitching from the right side of the pocket to ensure the most attractive stitching on the outside of the garment but you can also stitch from the wrong side if you are happy with how your bobbin stitches are performing.

Turn the remaining edges under using 5/8" seam allowances. Press thoroughly.

Place the pocket onto the shorts back using the pocket placement markings. I like to pin the pockets in place and then hold the two shorts back pieces with right sides together to ensure that the pockets are exactly aligned with each other.

Stitch around the pocket sides and bottom using 1/8" edgestitching and the optional extra row of topstitching. If only adding edgestitching, you can add a sturdy upper corner to your pockets by completing your edgestitching with a small triangle shape as pictured above.

Add the flap above the patch pockets by placing it pointed up with the right side of the flap (the more attractive side of the buttonhole) facing the right side of the shorts. Align the raw flap edge with the top of the pocket. Stitch 5/8" up along the pocket flap markings.

Trim the excess seam allowance from the pocket flap. Press the pocket flap down.

Stitch the pocket flap down by edge stitching and top stitching across the top of the flap. This will also enclose the raw seam allowance.

Repeat this process for the second pocket and flap. Add the buttons to your pockets at the marking. And now your pockets are complete!

Bamberton Shorts Sew-Along: Day 4 - Back and Front Seat Seams

Sew along this center front line and then stitch the entire center front and seat seam a second time for added strength in this high wear area.

Open up the shorts front and position them on your ironing surface with wrong side up. Press the mock fly and seam allowance towards the left front (if you were wearing the shorts).

Flip the shorts over so the right side is visible. Use the stitching template to mark the fly topstitching on the left front of the shorts (this is currently on the right side of your work surface).

Topstitch along this J-stitch line to secure the mock fly in place. Next, complete the seam underneath the fly by edgestitching 1/8" from the seam. Optionally, match the faux flat fell seam on the back of the shorts by adding a row of topstitching 1/4" from your edgestitching.

Next we will be assembling the fronts and backs along the inseam and side seams!