Today I’m going to walk you through the construction of our new Bifold Wallet sewing pattern. Of the three wallet designs in our shop, this one is the most complicated – but don’t worry, it is still perfectly suitable for a beginner sewist and it is certainly a very quick project for someone with experience!

We will be creating the fabric variation complete with the optional zippered coin pocket today. This way you can have a set of photos and extra tips to help you through the trickiest details. If you are absolutely new to sewing, I would recommend giving the Felt & Specialised Materials variation a try first. If you prefer to sew the Fabric variation, consider leaving the zippered coin pocket off on your first go.

Let’s get started!

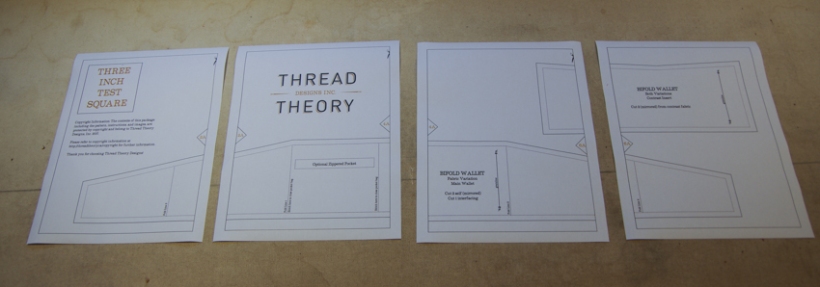

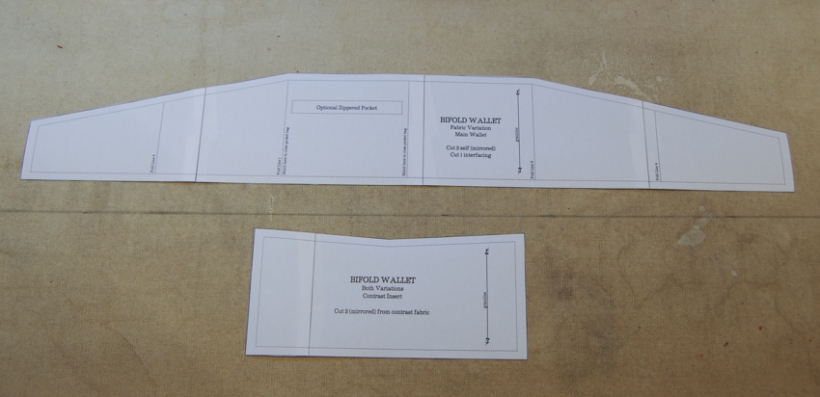

Print your PDF pattern as instructed within the Read Me First document. If you need extra help determining the correct printer settings, have a look at our PDF Pattern tutorial.

Cut the right hand margin off each page – there are little scissors pictured along each margin to show you where to cut.

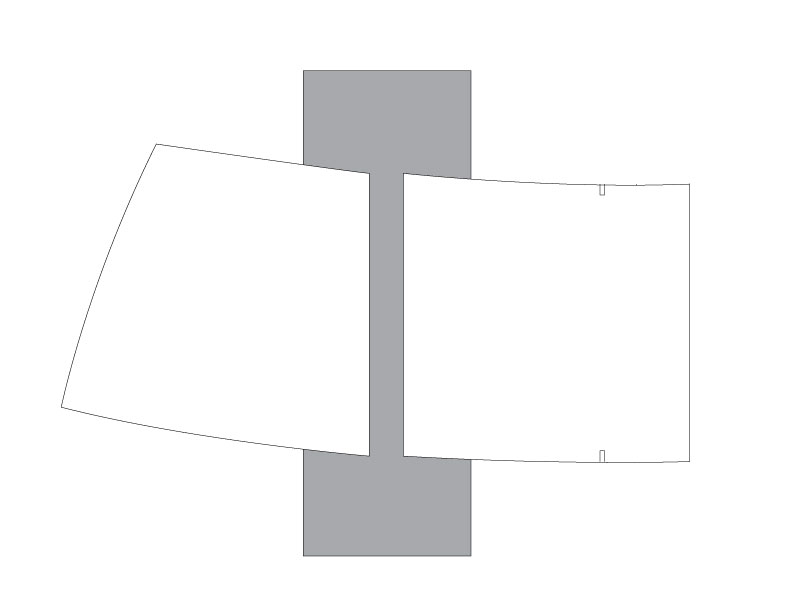

Align the numbered and lettered triangles so they make a perfect diamond and connect the four pages with either glue or tape.

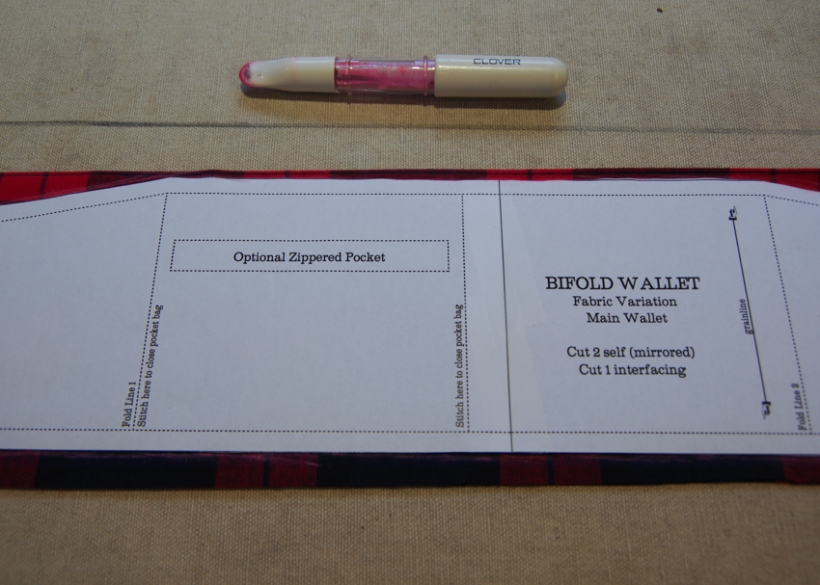

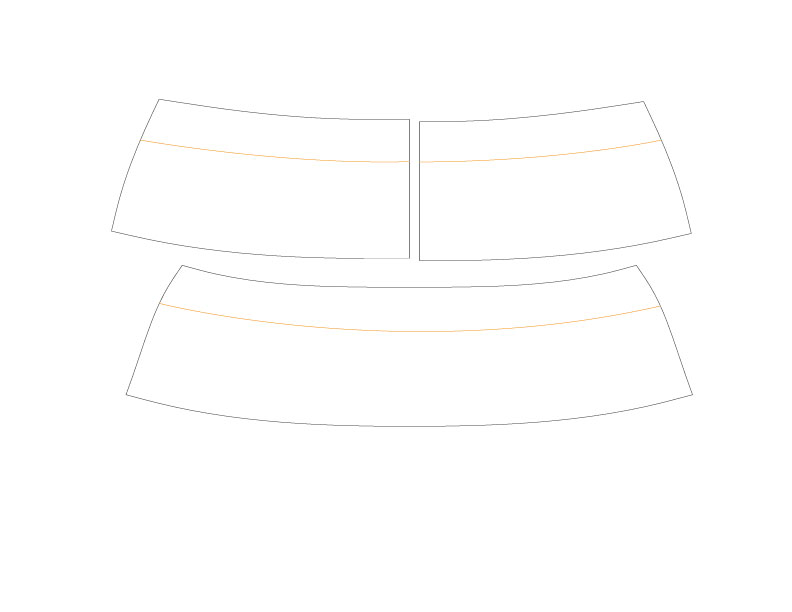

Cut out the pattern pieces so that they are ready to use:

For this wallet project I am using a scrap of cotton shirting fabric. If you are new to sewing you might like to choose a light and stable fabric such as cotton shirting or quilting cotton. You can also select a large range of other woven materials such as sturdy canvas, linen, or even flannel.

Iron any creases out of your fabric and fold it in half. Place the Main Wallet pattern piece on top of your fabric and either pin it in place to cut around or trace it with chalk or another marking implement.

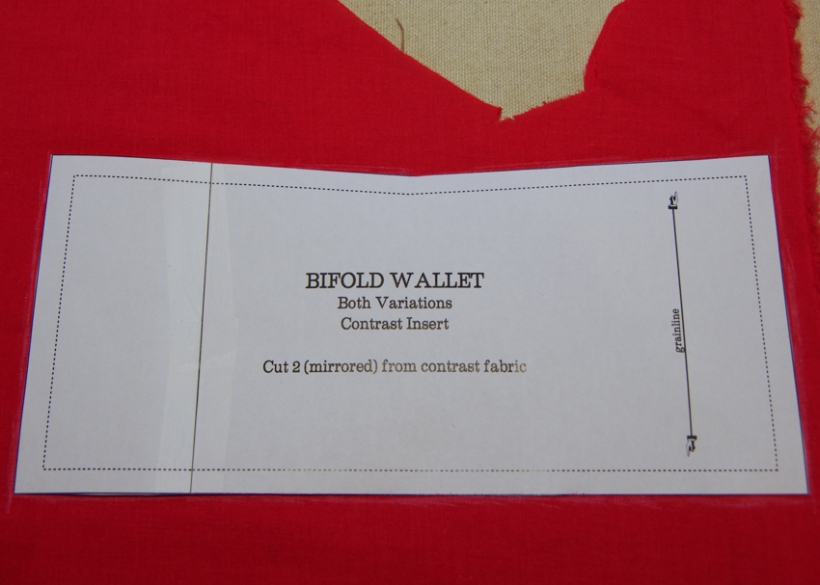

For the optional Contrast Insert, I have chosen a scrap of lightweight cotton batiste. Sewing wallets sure is a great way to use up small leftovers from bigger garment projects!

Fold the fabric in half to create two layers just as you did for the Main Wallet. Trace or pin the Contrast Insert.

Since my main plaid shirting is so light-weight, I chose a very stiff sew-in interfacing for this project. You can choose between medium or heavy weight interfacing to suit your fabric choice. If you are working with a stiff canvas you will not need a sturdy interfacing to provide structure but if you are working with a lightweight fabric like mine you will need to rely on the structure of the interfacing to create a wallet with substance and strength. Both fusible and sew-in interfacings will do the job!

Cut out all of your fabric pieces – you should have two main wallet pieces, one interfacing piece, and two contrast inserts.

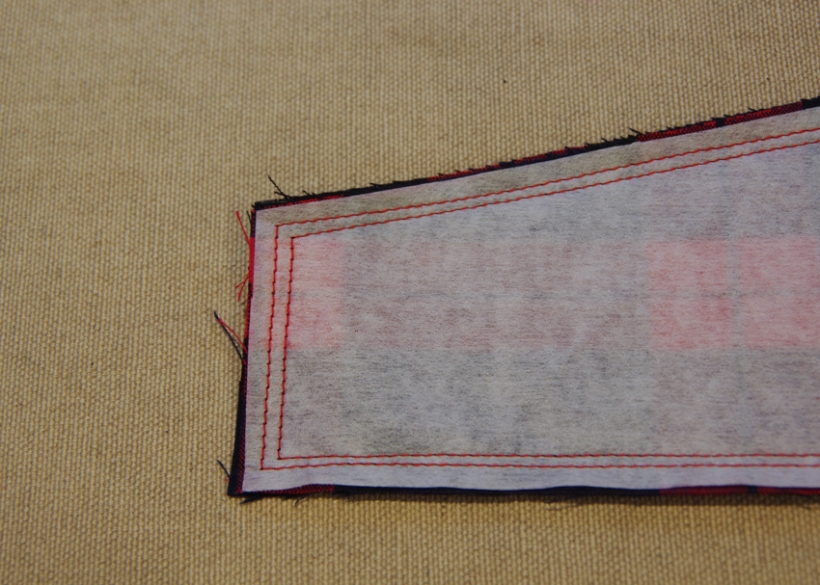

Apply your interfacing to the wrong side of one of your main wallet pieces – it doesn’t matter which one! If you are using fusible interfacing you will need to iron the interfacing on to the fabric. I am using sew-in so I stitched my interfacing to my fabric within the 1/4″ seam allowance:

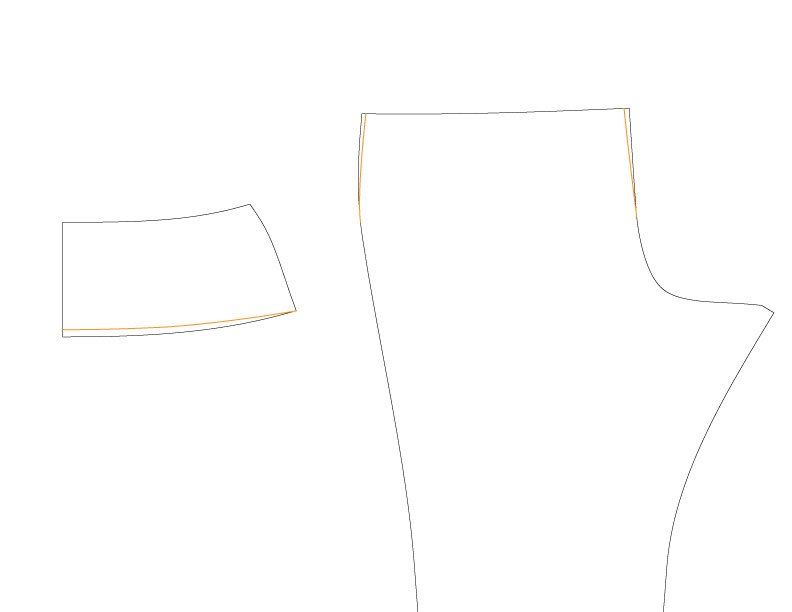

Now is a good time to transfer the Main Wallet markings on to the fabric. Transfer them to the interfaced piece. Here is how I like to do this:

Lay the fabric on your work surface with right side up. Lay the paper pattern piece on top. Shift the pattern piece up slightly (as photographed above) and continue each fold line onto the fabric with chalk.

Repeat this process on the top edge of the wallet by shifting the paper pattern piece down:

Use a ruler to connect the two vertical lines.

Transfer the zippered pocket markings by placing a pin through each corner. The pin is piercing the paper pattern piece and the fabric.

Flip the pinned pieces to the interfaced wrong side so you can see the sharp ends of the pins poking through. Place a new pin exactly where the sharp ends pierce through the fabric.

Here’s how this looks from the other side when you’ve finished adding pins:

Now remove the paper pattern piece and the first set of pins by pulling the paper off of the fabric. You will be left with the sharp ends of four pins sticking up:

Now use a ruler and chalk to “connect the dots” between the pins.

Prepare to add the zippered coin pocket by adjusting your stitch length to very short and trace the chalk marking with stitches.

These stitches will prevent the zipper window from becoming stretched and misshapen during the next steps.

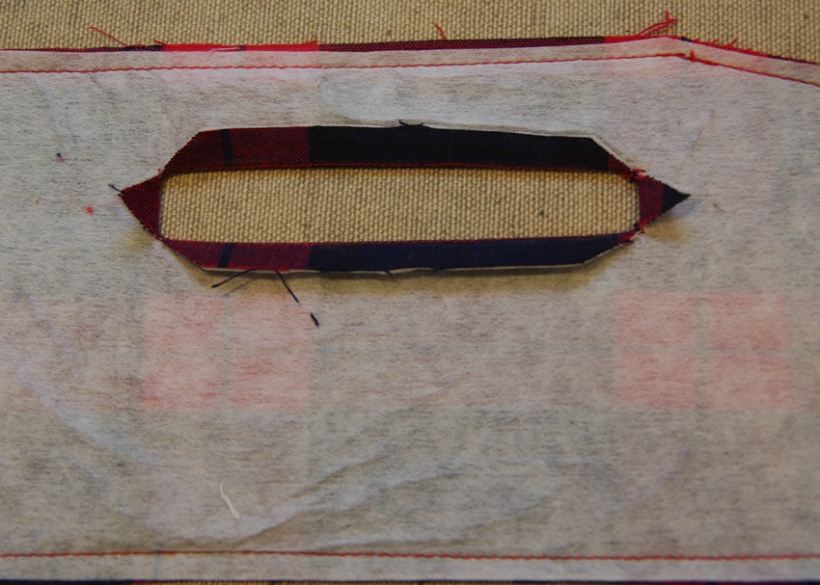

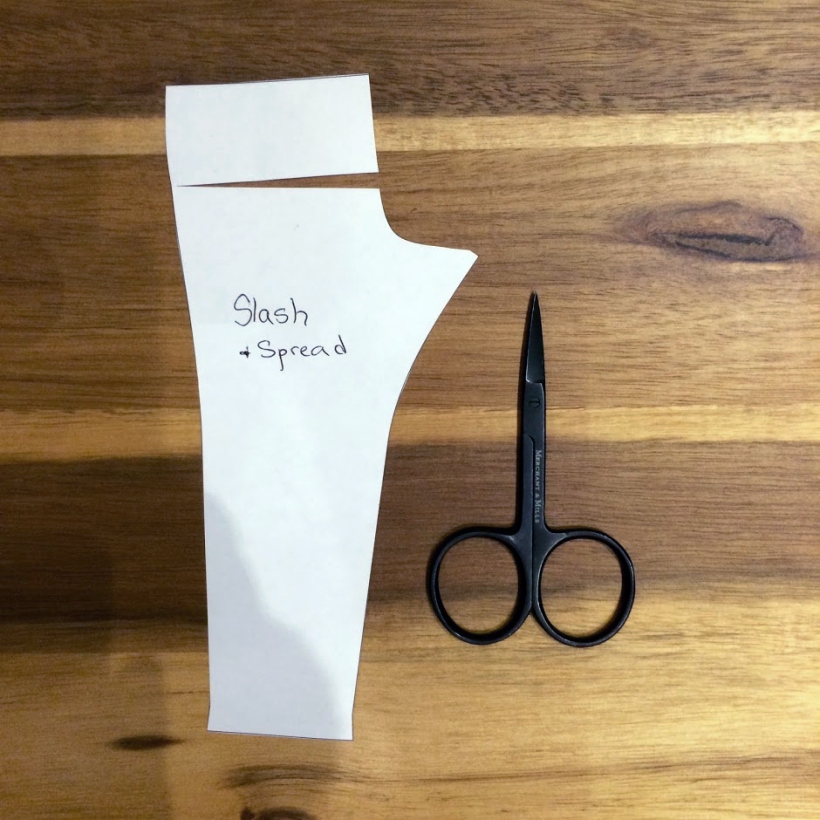

Slice open the zipper window by cutting horizontally along the middle of the window. Stop approximately 1/4″ to 1/2″ from both sides. Cut the shape of a Y towards each corner.

When cutting in to each corner, clip as close to the stitching as you can without actually cutting through the stitching. The closer you manage to cut to the stitching, the more square and precise your window corners will become.

From the wrong side of the wallet, press the zipper window open. Take your time with this pressing to ensure the stitching is not visible from the right side and that the corners are square.

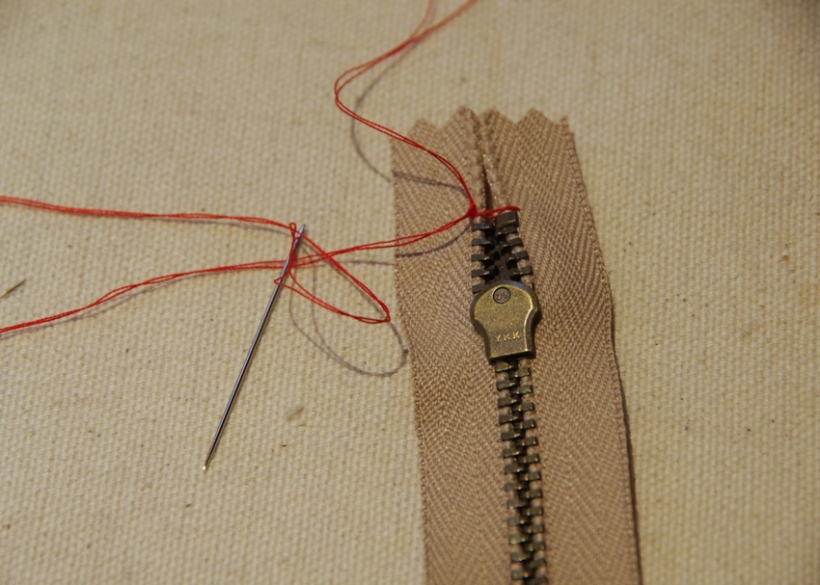

Now it is time to add our zippers! The zipper window is 3 3/4″ wide so we need to shorten our zippers to suit the window. If you are new to inserting zippers you might like to work with a plastic zipper for your first go as bulky metal teeth can make it tricky to create neat topstitching.

Begin your zipper preparation by closing the zipper and hand sewing the top of the zipper closed. This isn’t necessary but it is very helpful because you will need to open your zipper during the sewing process and the stitching will keep to top of it from splaying open while you stitch.

Measure 3 3/4″ (9.5 cm) from the top of your zipper to find the new end. Stitch around the zipper teeth by hand to create a new zipper stop.

Trim off the excess zipper tape. If you are using a metal zipper you may want to use pliers to remove excess teeth so that you don’t have to worry about breaking a needle when you sew over them. Alternatively, you can use precise scissors to cut the teeth off.

Place the zipper under the zipper window and pin in place. Make sure that the zipper teeth are centered in the window and that your hand stitched zipper stops are not visible. Fiddle with the window until none of the staystitching is visible (add as many pins as you like!). As you can see below, my window corners need some more fiddling and pinning:

Using a narrow zipper foot on your sewing machine, topstitch around the zipper window. Take your time at either end of the zipper and possibly hand crank the machine to ensure your stitching is straight as you go over your zipper teeth. Also, open the zipper when you reach the zipper pull so that it is out of the way and does not interfere with your straight stitching.

Once you have finished your toptsitching take a look at your corners to see if you are happy with how they turned out. If you see too much staystitching and your corners are not square, you may want to rip out your stitches and try again.

If you have used a plastic zipper, you have the option to cover up the two messy ends by creating a buttonhole stitch (a zig zag stitch with a very short stitch length) along the left and right sides of the window. If you have used a metal zipper you do not have this option because it is impossible to zig zag over the metal zipper teeth. Don’t stress yourself by aiming for perfection, by the time the wallet is finished small glimpses of staystitching will not be very noticeable!

Now we are ready to assemble the main wallet. Begin by placing the two main wallet pieces right side together and pinning.

Stitch around the entire wallet leaving a 4″ opening along the bottom so that it can be flipped right side out. The extra row of stitching in the photo below is the basting that attached my sew-in interfacing to my main fabric.

Here you can see the 4″ opening along the bottom:

Trim one seam allowance shorter than the other if you are using a bulky fabric. Since my interfacing is very stiff and bulky, I trimmed it extensively.

Clip across the corners so that they are easier to turn right side out without bulk and bunching.

Flip the wallet right side out through the 4″ opening. I used a point turner tool to ensure all my corners were nice and crisp. You can also use a pencil or chopstitck for this job!

Give the wallet a careful press and press under the seam allowances on the 4″ opening.

Handstitch the opening closed:

Close the side of the zippered coin pocket by topstitching down the center of the wallet.

The left side of the coin pocket will be closed by more topstitching later.

Now let’s make this long strip of fabric actually look like a wallet! Begin by pressing the wallet in half (in the picture below the zippered coin pocket is against the work surface.

Open the wallet back up and press along fold line 1.

Open it back up and then press along fold line 2.

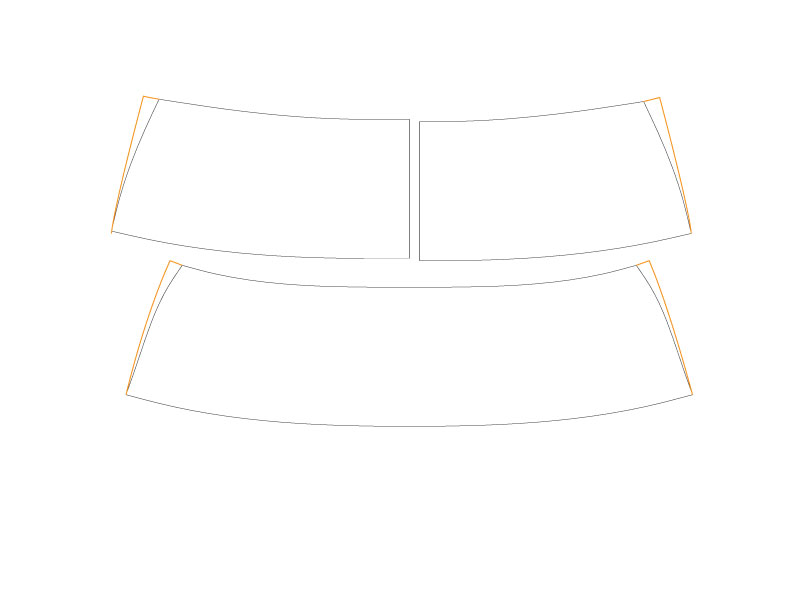

Press along fold line 3 and 4 so that the slanted card slots slope down towards the side of the wallet. Notice that there is a small gap at the spine of the wallet – this is to reduce bulk in the middle of the wallet so that it can close flat easily.

If you are sewing the optional cash insert, now is the time to stitch the two layers with right sides together. Leave an opening at the bottom so that you can flip it right side out. Before flipping, trim any bulky seam allowances and clip across the corners:

Press the insert crisply. Open your wallet flat and place the insert on top of the wallet between fold lines 1 and 2. Notice that the insert does not quite extend from fold line 1 to 2 (it’s a bit narrower).

Refold the wallet and pin the insert in place so that the left and right sides sit exactly at fold lines 1 and 2.

This will mean that the main wallet buckles slightly at the spine – this encourages the wallet to close flat as well.

Edgestitch around the sides of the wallet and along the bottom. Leave the spine free of edgestitching. It is important to keep all the fabric layers even so that you don’t miss the card slots or cash insert while edgestitching. I like to stitch from the outside of the wallet to make sure that my stitching looks attractive and straight on this side (after all, this is where the stitching will be most visible).

In the two photos below you can see where I edgestitched – in the first photo edgestitching is visible on the left hand side (this closes the left hand side of the coin pocket) and along the bottom. The stitching stops before it reaches the gap at the spine.

From the inside of the wallet you can see the stitching along the right hand side (where it keeps the cash insert in place) and along the bottom. The stitching stops prior to center where the card slots end.

And that’s all there is to it! Fill up the wallet with your cards or perhaps fill it with gift cards, notes and photos if you are giving it as a gift. In the photos below I’ve filled it up with everything I carry in my wallet on a daily basis – this includes 8 cards, approx. 5 or 6 coins and a bit of cash.

Please don’t hesitate to comment if you have questions about the sewing process! I would love to help!

Have fun sewing such a quick and practical project!

Get the Bifold Wallet here.

Get the Wallet Gift Giving Set (includes 3 projects) here.

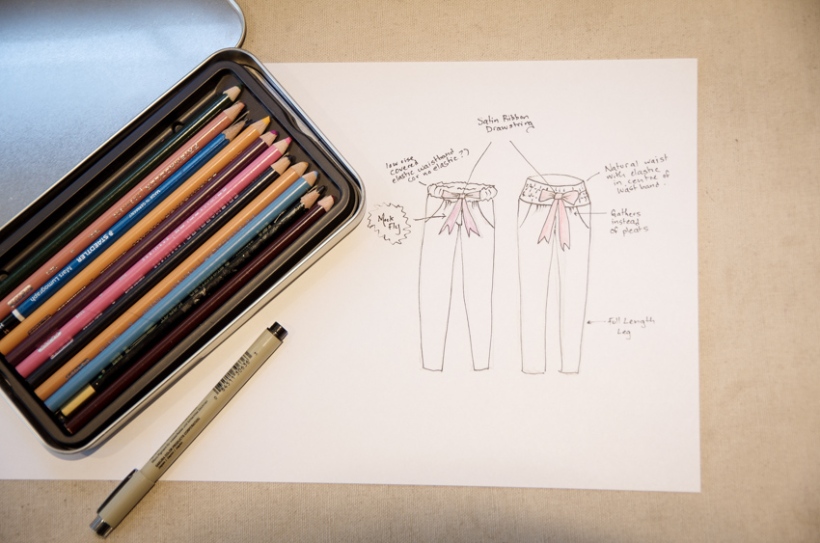

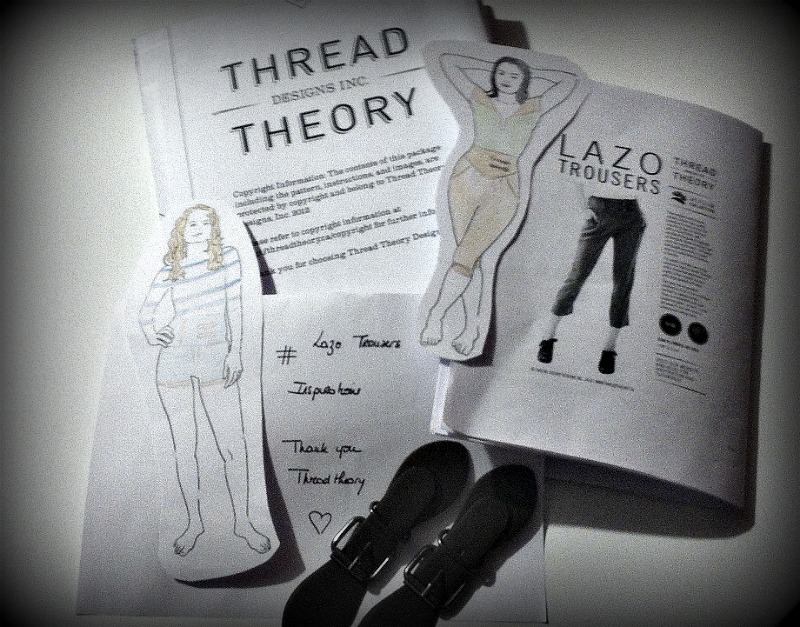

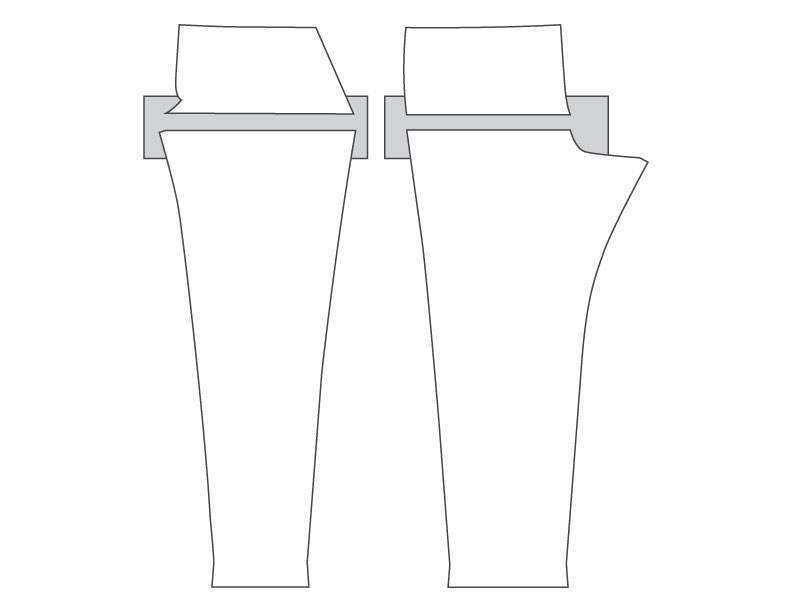

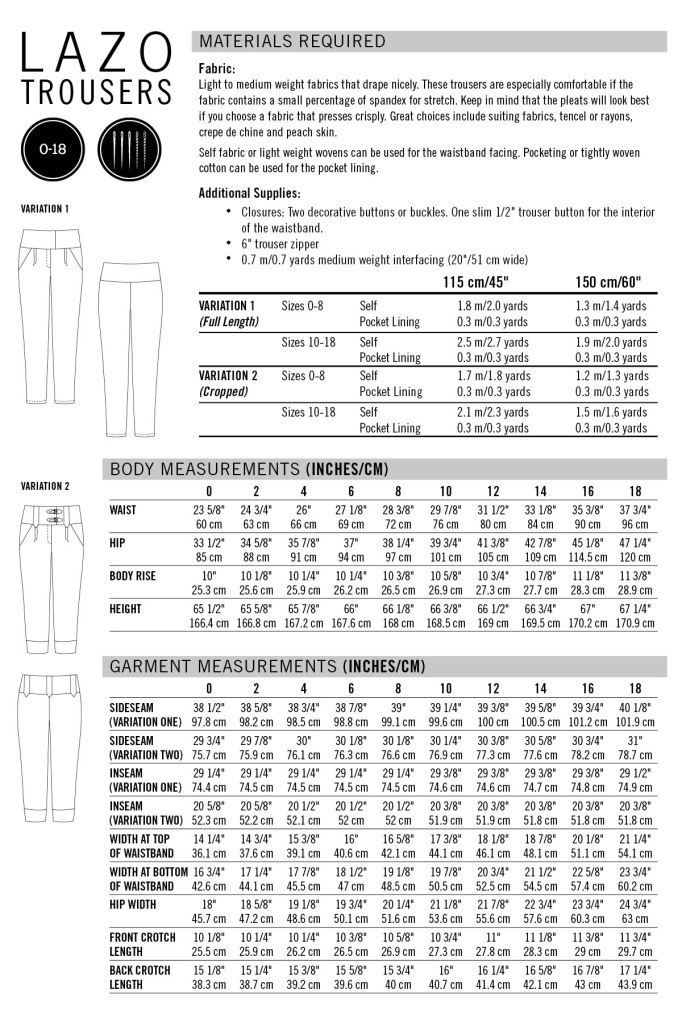

Today’s post is meant to get your creative juices flowing before you have a chance to cut into your Lazo Trousers fabric. I imagine many of us will be too busy spending time with family until the end of the month to actually delve in to sewing something for ourselves – that’s no problem! It just gives you more time to daydream about your creations and post about your pattern hack ideas!

Today’s post is meant to get your creative juices flowing before you have a chance to cut into your Lazo Trousers fabric. I imagine many of us will be too busy spending time with family until the end of the month to actually delve in to sewing something for ourselves – that’s no problem! It just gives you more time to daydream about your creations and post about your pattern hack ideas!