Sew-along with us!

Perhaps you'd like some company while you sew? We've sewn up each of our patterns and photographed each step along the way. Find the pattern you're after in the filter drop down below left.

Sew-Alongs

Fairfield Button-up Sew-Along: Day 12 - The Collar

Today’s post will cover the last big hurdle when sewing a button up shirt: the collar. Let’s begin:

First, let’s stay stitch along the shirt neckline using a scant 1/4″ seam allowance. This stay stitching serves two purposes: 1) It prevents the neckline from stretching out as we work with it and 2) it allows us to clip into the seam allowances without the fear of fraying beyond the allowance.

Clip every 1-2″ along the neckline up to your stay stitching. This will allow you to lay the neckline out flat and fairly straight.

Now to assemble the collar:

Pin the upper collar and under collar with right sides together. You will notice that the under collar is very slightly smaller than the upper collar – this is to provide enough room in the upper collar for the collar to curve gently over the collar stand.

Stitch around the two sides and the long top edge of the collar using a 1/4″ seam allowance. Leave the bottom of the collar (where the collar attaches to the collar stand) free of stitching.

Grade the seam allowances and trim the corners to reduce bulk.

Turn the collar right side out and press. When I press collars I like to gently push out the corners with a point turner (or chopstick) and then ever so slightly roll the seam towards the under collar. This will ensure that the seam doesn’t roll to the upper collar during later steps.

Pull the two remaining raw edges so that they are even and the upper collar is relaxed and slightly bubbled. Baste the raw edge closed using a 1/4″ seam allowance.

Finish prepping your collar by top stitching 1/4″ from the collar edge around the two sides and the top of the collar. Don’t forget to complete this step! I have forgotten to do this a couple of times and forgot to take a photo of the stitching this time. I don’t know why this step slips by me so frequently! Here’s a photo of a finished collar so you can see the 1/4″ top stitching:

Now we can attach our collar stand and collar to the shirt! Exciting!

Pin one collar stand (the interfaced stand if you only interfaced one of the two collar stands) to the shirt neckline, right sides together. Align the notches with center back and the shoulder seams. The collar stand should extend exactly 1/4″ beyond either end of the shirt neckline (this is the seam allowance).

Stitch across the neckline using a 1/4″ seam allowance:

Grade the seam allowances (I trimmed the neckline seam allowance and left the collar stand allowance whole). Press the allowances towards the collar stand.

Pin the collar to the collar stand so that you can see the upper collar. The under collar will be against the right side of the collar stand. The collar will fit between the two notches.

Baste the collar in place using a 1/4″ seam allowance.

Prepare the remaining collar stand by pressing under the 1/4″ seam allowance along the bottom of the stand (this is the part that attaches to the shirt).

Pin the remaining collar stand atop the collar so that the right side of the collar stand faces the upper collar.

Begin at one end of the collar stand exactly where the stand extends beyond the shirt placket. Stitch around the collar stand using a 1/4″ seam allowance and end exactly at the other shirt placket.

Here’s how it looks from more of a distance:

Complete the collar by carefully pinning the folded edge of the collar stand over your neckline seam. I like to use quite a few pins for this job to make sure the collar stand won’t slip or stretch.

You can choose at this point to baste the collar stand fold in place and then stitch from the right side of the garment or you can stitch from the wrong side of the garment. I usually stitch from the wrong side of the garment because Matt wears his shirts open at the collar – this means the most visible stitching is either tip of the collar stand on the insiderather than the outside.

Either way, edge stitch 1/8″ from the collar stand edge around the entire stand. If you like, you can tuck a garment tag into your collar stand bottom before you edgestitch:

Finish your collar by giving it a thorough press. I like to encourage the collar to shape nicely by pressing on a tailor’s ham so that the collar rolls over gently and the collar stand takes the rounded shape of the wearer’s neck. You can see the bend in my collar in the photo below:

I encourage you to explore a different method of creating a shirt collar with each shirt you make. There are many interesting methods, a few of which are well documented online. They all use the same pattern pieces so you can work with all of them while sewing up a batch of Fairfield Shirts. Pick the one that suits you best or meld together your favorite elements of each for your own unique method!

Here are some resources for different collar construction methods:

- The same method that I prefer – clearly represented (as is the case with all of her tutorials!) at four square walls.

- David Coffin’s method (as explained on the Sewaholic blog).

- The method used for the Archer Shirt as demonstrated on the Grainline Studio blog.

- A detailed description of how to iron the collar to ensure a very crisp seamline.

How did it go? Does your collar look super professional? I hope you are proud of yourself! This is some pretty fiddly and precise sewing you have accomplished!

Fairfield Button-up Sew-Along: Day 13 - Hemming and Buttons

It’s the last day of our sew-along today! You're beautifully sewn shirt is just about ready to wear.

To finish our shirts, let’s begin with the hem – a quick and easy task! Press up the hem allowance 1/4″:

Press up the hem again 1/4″ to enclose the raw edge:

I like that the curved hemline at the hip doesn’t interfere with pressing the hem. It’s just the right amount of curve to provide shaping without bunching up at the peak.

Stitch along the entire hem.

And now, let’s move on to our buttons! While many people dread sewing buttonholes (I can’t say I look forward to them myself), there is no need to get too uptight – just use a few tools and tricks and you will be surprised how professional they look when you are done!

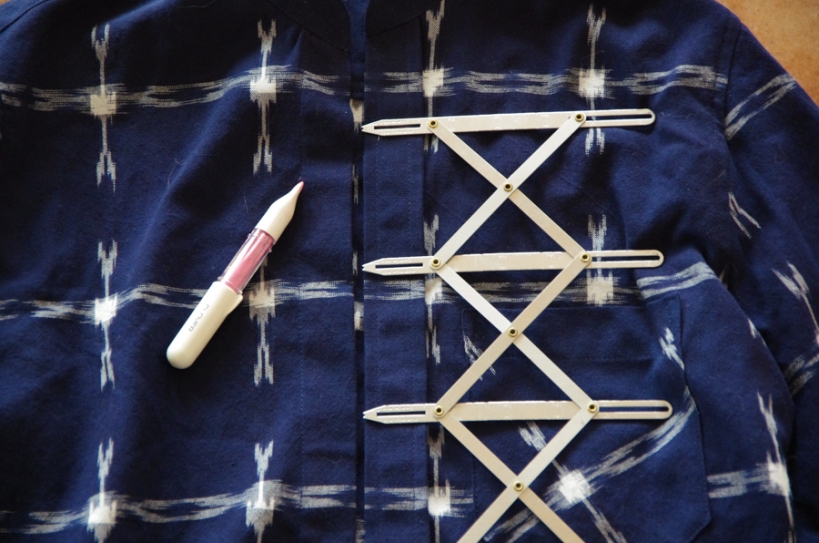

I like to use our expanding gauge to mark my buttonholes. I generally ignore buttonhole markings on the pattern pieces and instead place my primary buttonholes at important points before spacing the rest evenly between them. When sewing shirts for Matt I ensure that a button is placed at the widest point of his chest and also that the top button is placed nicely. He likes to leave the collar stand button undone (as most men do when they are not wearing a tie) so it is important that the top button is not set too low so as to expose a bunch of chest hair or something! If the person you are sewing for has a rounded belly, make sure to put a buttonhole at the area of greatest strain so that the shirt does not pull open.

Even though the buttonholes are sewn vertically, I like to make a horizontal marking – this way I can use this marking as a placement for my presser foot and the top of the buttonhole. I then use my placket top stitching as a guide to keep the buttonhole exactly in the center of the placket. The top stitching is easier to see while sewing with a buttonhole attachment than a vertical chalk marking would be.

Make sure to make a practice buttonhole before you begin on your shirt! I tend to choose a buttonhole length that is slightly longer than my button. For instance, I am using 3/8″ wide buttons (from our shop) for this shirt so I sewed a 1/2″ buttonhole. This extra length allows the button to slip in and out easily.

Apply your buttonholes to the collar stand, shirt front, and cuffs. If you like, sew the bottom button hole on your shirt front horizontally. You could even opt for a fun contrast thread for this bottom buttonhole. This flashy little detail is quite common on store bought shirts and is a great way to add a bit of creative flair to such a traditional garment.

I find the trickiest part of sewing buttonholes actually occurs after the sewing is finished! It is quite devastating to make a mistake when cutting open your buttonhole.

My favorite way to open buttonholes is with the extremely sharp chisel that we sell in our shop. I didn’t even need to use a hammer to cut these buttonholes – I just pressed down with the chisel and they sliced open in the most satisfying manner.

The chisel is 1/2″ wide so it was the perfect width for my buttonholes. The inside of the hole looks so tidy when it is cut this way!

Alternatively, you can use some sharp and precise scissors (such as the Merchant & Mills buttonhole scissors in our shop) or employ your seam ripper.

I highly recommend using a fresh and sharp seam ripper and a preventative pin at either end of the buttonhole to prevent cutting through your buttonhole and adding a gaping slice to your carefully sewn shirt! You can see how this preventive pinning technique works near the bottom of this tutorial by Made Everyday.

Lastly, it’s time to add our buttons! If you are matching stripes across the shirt, be very careful with your button placement. Position the button so that it will sit near the top of each buttonhole. If you simply place the button at the center of each buttonhole you will find that the buttons slip up to the top of the holes during wear and your stripes will look like they are not properly matched!

If your buttons tend to work loose or fall off over time (mine used to constantly!), you might like to check out the button sewing technique that I learned in design school. It was (almost) worth the cost of tuition to learn this technique alone!

And, that’s it!!! We are done!!! I hope you’ve enjoyed following along with this sew-along. I can’t wait to share some of your finished Fairfield Shirts next Friday. Be sure to share your makes by email (info@threadtheory.ca) or by using #fairfieldbuttonup

Even if you can’t photograph your shirt on a model (don’t ruin the Father’s Day surprise for your dad by asking him to model before Sunday!), you can photograph your shirt hanging from a clothes line or pleasingly folded up beside your sewing machine. Whatever sort of photo shoot you come up with will be perfect – it makes my day seeing your finished makes, your fabric choices and your design decisions.

Thanks for following along! Happy sewing!

Fairfield Button-up Sew-Along: Day 14 - The Parade

Today I want to show you an inspiring selection of Fairfield Button-up Shirts sewn by you as well as the finished Ikat Fairfield that I sewed during our sew-along.

Matt really loves this print and I think the indigo blue looks lovely with his brownish/blue eyes.

I’m really happy with the casual look that the contrast Tagua Nut buttons gave to the shirt. The amber color looks very summery against the blue – like the sun against a blue sky!

I decided to sew the buttons on by forming a cross with my shirt to echo the print of the fabric (usually I sew two horizontal lines when working with four hole buttons…sort of like train tracks). I’m not sure if this echoing of the motif is too subtle that it is virtually unnoticeable. I notice it though!

Matt really likes how the print placement worked out on the back yoke. I’m glad I decided against placing the yoke on the bias. I think the print was just a bit too large in scale for this cutting technique to have been effective. I’m pretty pleased that the print matches along the collar and yoke at center back!

With all the shirt sewing that I’ve been doing lately, Matt’s closet is beginning to look quite fresh and full! I have been choosing his fabrics with a general theme of “blue and bright” since last winter his wardrobe had become almost exclusively dull brown and olive green. The influx of a few bright colored items has made a huge difference! I might do a photo shoot of his new shirt wardrobe soon – all of the prints and colors look really nice together.

Now, the best part of this blog post – it’s time to show off your Fairfield Shirts!

_ym.sews_ achieved beautifully crisp cuffs and excellent print placement for her plaid Fairfield. I love the careful use of contrast fabric for the cuff facing, collar stand and yoke facing!

tiny_needles whipped up this Fairfield so quickly! It was the first Fairfield Button-up that I saw in the wild after our pattern release. Her boyfriend wore this very dapper shirt for their anniversary celebrations.

One of our test sewers, Sarah, sewed this fresh and summery Fairfield for her husband. I like how the sleeve tabs add such versatility to this shirt. With the sleeves full length it looks very dressy but with the sleeves rolled up it takes on an airy and comfortable vibe that could easily work with brightly colored shorts!

After completing her first Fairfield Button-up, Sarah immediately cut out another one – this time for her brother! She had a lot of fun playing around with the stripes (she added a seam down center back) and she added some hidden froggy details. Isn’t the frog peaking out of the front pocket such a great idea?! She added a lining to the pocket to achieve this detail.

After completing her first Fairfield Button-up, Sarah immediately cut out another one – this time for her brother! She had a lot of fun playing around with the stripes (she added a seam down center back) and she added some hidden froggy details. Isn’t the frog peaking out of the front pocket such a great idea?! She added a lining to the pocket to achieve this detail.

These three Fairfields have been sewn by bego_aguilera_caballero, Ana, and sewing_dutch. The whimsical print on Begoña’s shirt is just lovely (especially with those dreamy houseplants as a backdrop). Ana sewed the band collar (available in our Alternate Collars free download) on her green linen shirt. The band collar and linen are a match made in heaven! Lastly, the subtle floral yoke adds such hanger appeal to Becca’s shirt. She also sewed a striped grosgrain ribbon down the right front of her shirt which adds structure (for stronger buttons) and the perfect contrast if the top button is left undone.

And last, here is a great example by scaredstitchless of how much fun you can have when sewing a wearable mock-up! Quilting cottons provide a limitless palette of bold colors and unique prints. I’m impressed that she managed to find perfectly matched orange buttons!

Thank you, everyone, for joining me on the Fairfield Sew-along and for sharing your Fairfield photos by emailing me or by using #fairfieldbuttonup ! It’s been a thrill to see how smart your shirts look. If anyone has wrapped up their shirt to give on Father’s Day, I look forward to hearing about the grand reveal!

Jedediah Sew-Along | Getting Started

- Preparations - Fabric Requirements, Garment, and Body Measurements making bias binding from a vintage handkerchief

- Lengthening or Shortening a Sewing Pattern Tutorial - Learn how to adjust the length of the Jedediah Pants before cutting them into your fabric

- Grading to Create a Custom Fit Tutorial - If the body measurements given aren't a perfect match, consider grading to create a custom fit!

The Jedediah Pants Sew-Along will be separated into 5 segments for easy to follow, step-by-step images, and tutorials:

2. Finishing seams using bias binding and the flat felled seam method (back yoke, inseams, and side seams)

For inspiration check out #Jedediahpants on Instagram and our community Pinterest board

Jedediah Sew-Along | Front and back pockets

Jedediah Sew-Along | Finishing seams (back yoke, inseams, and side seams)

- Front pant

- Back pant

- Back yoke

- Scissors

- Bias binding (optional)

Jedediah Sew-Along | Sewing a fly zipper

- Zipper

- Zipper shield

- Scissors

- Fusible tape (optional)

- Marking pen and ruler

Double-check that all markings are transferred from your pattern to your front pant legs at the center front and the waist edge.

Finish the crotch seams and fly facing edges before you sew up the seat seam. Options include serging, zig-zagging, or binding.

Tip: If you are using a bulkier material you may want to avoid using binding for the seat seam — this is a better treatment for lighter weight pant fabrics.

Serging or zig-zagging the entire seam and then strengthening the seam using topstitching (this step is included later on in the instructions) will create a stronger and less bulky finish for these close-fitting pants.

Stitch until 1/2" (1.3 cm) below the zipper placement mark at the center front. Check that your seams line up nicely and reinforce this seam by stitching over it one or two more times (this is an area that needs to be very strong). Refrain from pressing this seam until you are finished sewing your fly.

The Left Front (if you were wearing the pants) will act as the TOP, the most visible part of the fly. Fold and press the left front fly extension to the wrong side at the notch FURTHEST from the curved fly facing edge.

With the right sides together, line up the right-hand side of the zipper tape with the finished edge of the LEFT FRONT fly extension. Use a zipper foot to stitch the zipper to the FLY EXTENSION ONLY. Make one line of stitching close to the zipper teeth, then make another closer to the edge of the zipper tape.

Jedediah Sew-Along | Belt loops and waistband

- Belt loops

- Waistband + waistband interfacing

- Bias binding (optional)

- Pants

- Button

- Seam ripper or buttonhole making tool

- Press under one long edge to the wrong side at 3/8" (1 cm).

- Finish one long edge with a serge or zig-zag stitch

Apply binding to the other long waistband edge.

Pin both layers of the waistband in place with the inner waistband lying unfolded from the stitched corner onwards (as shown). From the right side of the pants, topstitch along the lower edge of the waistband.

Flip the belt loop up and loosely curl the top edge under 1/4" (0.6 cm).

Jedediah Sew-Along | Hem and cuffs

Stitch 1/8" (0.3 cm) away from the folded hem edge.

If you are sewing the Pants Variation you are DONE! Give your garment a final press and your pants are ready to wear!

Your shorts are DONE! Give them a final press and they are ready to wear!

Mahle Tie Sew-Along

• 1 yard (1.1 meters) of sew-in wool or wool/nylon blend interlining

• Silk thread

• Hand sewing needle

• Microtex or fine point sewing machine needle (for sewing silk or rayon fabric)

• Beeswax

• OPTIONAL FOR QUILTING COTTON OR SIMILAR FABRICS: 1/4 yard (0.2 m) lightweight interfacing or canvas lining

• OPTIONAL: Source your interlining materials from a vintage tie. To do this, carefully take the tie apart by ripping out the center seam. Gut the tie, trim the interlining and canvas pieces to size, and then use them as the inner material for your tie.

Stitch, using a 1/4" (0.6 cm) seam allowance, along the outer and diagonal edges towards the blade tip lining point, stopping 1/4" (0.6 cm) from the point.

Pin. An intentional bubble will form on the blade because it is wider than the blade tip lining.

Push the bubble out of the way so it stays at the point and doesn’t get stuck in the outer and diagonal edges. To make sure you don't accidentally sew the bubble, sew with the lining side up.

Stitch, again with a 1/4" (0.6 cm) seam allowance, along the outer and diagonal edges together towards the tie point. Your stitch line will match up with the previous stitch line.

Stitch across the blade point bubble using a 1/4" (0.6 cm) seam allowance. The stitch will end up being perpendicular to the diagonal stitch lines. Start by placing your sewing needle down in the center of the stitch line, leaving the bobbin and needle thread tails long and towards the back of your sewing machine. Gently pull on the thread tails when you start stitching. Stitch forward first until your stitches match the lining stitch lines. Then, backstitch off of the fabric. Tie the thread tails together to secure the stitch.

Fold the keeper loop in half once more aligning the long folded edges. Press. Edgestitch along the folded edges at a scant 1/4" (0.6 cm) seam allowance.

Insert the keeper loop into the blade opening at the measured point. Stitch the short edges of the keeper loop to the blade seam allowance, stitching within the blade seam allowance.

Cut a long strand of thread so that you can sew the seam together in one go. This will help to keep the natural fluidity of the finished tie. Run your thread through beeswax to prevent your thread from knotting up while sewing.

Begin at the tail end by backstitching a few times to anchor your thread. Sew along the seam creating long and loose slip stitches, about 1/2" (1.3 cm) apart. Be very careful that you are only sewing the seam together and not stitching into the tie front.

Press the keeper loop open so that it is flat and centered over the tie seam.

Using your hand sewing needle and silk thread tack the short folded edges of the keeper loop to the back of the tie, being careful not to stitch through to the tie front.

Woodhaven Apron Sew-Along Day 3: Hardware and Finishing Details

On the final day of the Woodhaven Sew-Along, we will go over the steps to complete the apron and how to install and attach the various hardware details to make your apron unique.

Rivets

For each variation, we recommend adding rivets to the pockets where indicated for extra reinforcement. Depending on the rivet tool you are using there are several ways to install your rivets. Refer to the instructions that come with your rivet tool to install the rivets.

Due to the bulkiness of the fabric at the pocket corners, it may be helpful to use an awl to make a hole for the rivets.

Make a hole in your fabric that is slightly narrower than the rivet stem.

Following the instructions that came with your rivet setter tool, secure the rivets to your apron.

If you want to add more functional details to your apron, you can use rivets to install additional webbing loops for holding tools, towels, key rings, etc.

Grommets

Similarly to installing rivets, you will want to refer to the instructions on the grommet tool you are using to secure your grommets.

The grommets we used from Emmaline Bags have a screw back to secure the front and back of the grommet, so the only tool needed to install these is a small screwdriver similar to the one that comes with most home sewing machines.

**Tip: It may be helpful to jump ahead and hem the edges of your apron before installing your grommets, depending on the size, so you don't run into any issues with your presser foot.

Align one grommet with the placement marking on the apron. Trace a circle over the placement marking that is the size of the inner circumference of the grommet.

Clip and cut the fabric away inside the circle to create an opening for the grommet.

Install the grommet according to your setter tool instructions.

Hem

Hem your apron following the order in the instructions if you haven't already.

Straps

After installing the grommets, it's time to attach the straps.

*If you intend to add a buckle closure do not attach the straps to the chest yet

Cut the length of webbing roughly in half.

At the chest, thread the ties through the grommets and either create a large knot so the tie will not slip through the opening or fold and stitch in place to secure.

If you do not wish to install grommets to the chest of the apron, you can stitch the ends of the straps to the apron as shown in the image below.

Thread the straps through the waist grommets. Try the apron on a person or dress form and cut the straps to fit.

Buckle Closure

If you haven't already done so, cut the length of webbing roughly in half to create two straps.

To attach the slider, thread the webbing through the slider so that you have a tail several inches (centimeters) long.

Stitch the tail to the webbing to secure the slider in place.

Thread the other end of the strap through one end of the buckle closure.

Thread the end of the strap through the slider and adjust the length.

Repeat for the other strap and buckle closure piece.

Thread the straps through the waist and chest grommets. Adjust the length at the chest and cut to fit. Secure the straps at the chest following the instructions in the previous steps.

Show us your finished Woodhaven Apron by tagging us on Instagram (@threadtheorydesigns) using #woodhavenapron or send us an email at info@threadtheory.ca

Woodhaven Apron Sew-Along Day 2: Pockets!

Baste the short edges of the Pocket Flap to the zipper and pocket pieces following the basting line on the pocket.